Alpha Restoration & Waterproofing has been in the waterproofing and restoration business since 1983. We are a union contractor with additional insurance coverage for working on condominiums. We pride ourselves on being one of the leaders in the waterproofing and restoration business in the San Francisco Bay Area. Alpha Restoration and Waterproofing is one of the most renowned and reputable specialty contractors in Northern California.

With a reputation for solving most complex problems in the field of restoration and waterproofing, Alpha has been part of some of the most exciting and challenging restoration and waterproofing projects. Whether restoring the residence of a top diplomat or waterproofing structures on the fringe of the San Francisco bay, our company consistently outperforms all others in its class and our reputation offers limitless opportunities. Our repeat customer base is a testament to our dedicated service.

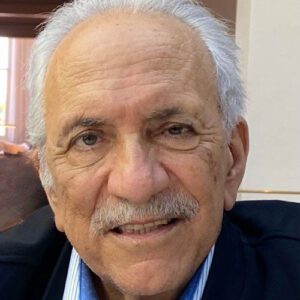

Emile Kishek

49 years of industry experience

Jack Tabri

36 years of industry experience

Chris Von Laufen

32 years of industry experience

2014 ICRI Award of Excellence

945 Green St, San Francisco, CA

2012 ICRI Award of Merit: Historic Category

Point Arena Lighthouse

2009 ICRI Award of Excellence

Lake Merritt Boathouse

Nulla porttitor accumsan tincidunt. Vivamus magna justo, lacinia eget consectetur sed, convallis at tellus.